When it comes to grouting or concrete repair, everyone knows that the mixing determines your pace. Conventional mixers, required mixing times and basic packaging all combine to slow your production during installation. Let’s face it, you can only mix so much so fast in a conventional mortar mixer.

If your project is going to require a lot of material to be placed in a short time, you’ll have to mix more and faster to get it done within the owner’s schedule and still make money. There are other options available. The question from most contractors is, “Can we do it?”. In this article, you’ll learn about unique equipment and special packaging that will give you options you hadn’t considered before.

Traditionally. Grouts and concrete repair mortars are purchased in 50lb bags and broken into a mortar mixer to be mixed 3-5 bags at a time. Workers have to handle every bag getting it to the mixer and then they have to handle every bag once it’s mixed with buckets to the form or floor. All this handling limits the amount of material that can be poured in any given time. As a general rule, 2 people on a mixer can mix 1 cubic yard an hour comfortably and you can count on a max of 4 cubic yards in a day. Sometimes, that’s just too slow given the magnitude of the job.

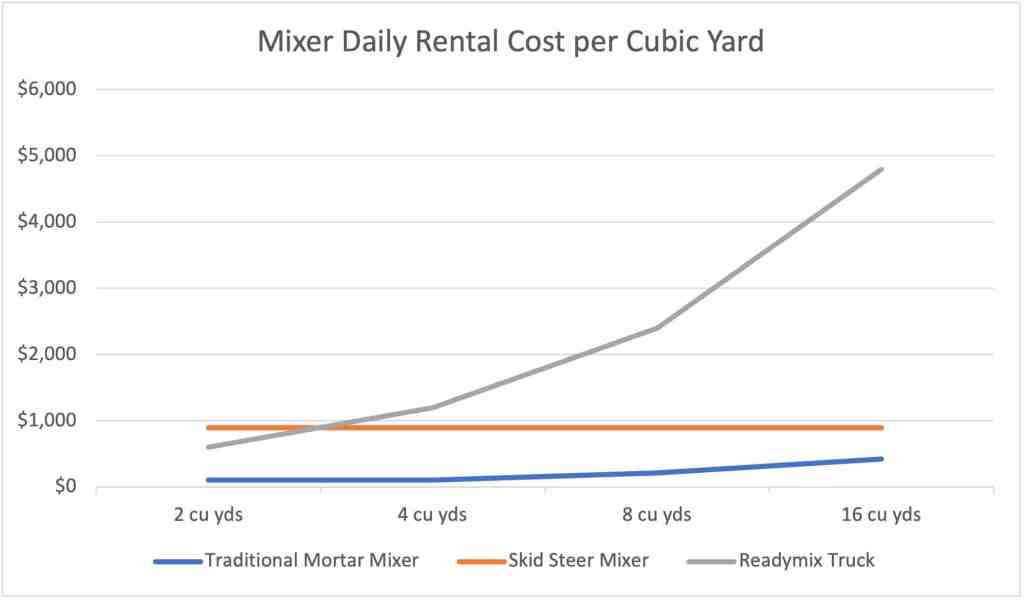

To address this issue, many manufacturers have offered these traditional materials in 3000lb bags. This allows for 3000lbs of material to be mixed in a single batch, thus speeding up the mixing process. However, the use of a ready-mix concrete truck is required to do the mixing and most of the concrete plants are not lining up to rent their trucks by the hour. They’d rather send them out full of concrete that they are producing. One other consideration, the truck needs to have rock as part of the material to properly mix it in its rotating drum. So, really thin placements might be impossible with this method.

While mixing more is key to improving your production, it’s not the only factor. Ready-mix companies will charge a premium for their trucks. However, if they need them for an emergency pour or to help a really good customer, they will pull them and you’ll have to conform to their schedule. You’ll also have to pay for each trip made by a truck as well as the water and rock loading in each. And, since most of these pre-packaged products are being used to save time on the schedule, you’ll only be able to mix a couple of 3000lb bags in each truck. That’s a rental charge incurred for every couple of yards or so.

The answer is to have a set rental rate for the day or week to keep rental costs low, to have the material packed so that it can be mixed faster and to have a system that gives you the most flexible schedule. That’s why we offer the mini-bulk bag system.

This system uses a prepackaged 800lb bag that can be broken at once into a mixer that can mix the full 800lbs in just minutes. This eliminates the need to handle of all those single bags and the excessive time wasted in touching every single bag. You’ll be able to mix 800lbs in the time it takes to mix 2 bags.

For deeper pours, aggregate extension can be added to the mixed material by dropping it right into the mixer by bag, shovel or skid steer.

This system also greatly reduces the number of people you would need to mix at the pace required for a fast pace job. It would take 12 people and 4 mixers to mix the same volume as 1 mini-bulk mixer and 2 people in one day.

Call us to discuss your next grouting or concrete repair job and see if Bulk materials and mixers can help cut your time and labor.

Share this: